Well Water Softeners and Iron Filters are special tools.

Even the worst well water problems can be fixed. You need to know (and follow) the rules of Water Chemistry. You also need the right tools, and know how to use them.

In 6 years, 3 water treatment companies had tried almost everything. Water Softeners, a Chemical Free Iron Filter, a Sediment Filter, and even Hydrogen Peroxide injection.

All 3 companies failed. They tried the wrong things. The water was horrible.

Our client had little hope, and a lot of frustration. Then he contacted Premier Water.

Step One – Get the Facts

We started with a Site Inspection. During this visit, we gathered the following information:

- Plumbing and drain requirements

- Well pump performance

- Onsite water testing + sample for further lab analysis

- Assess water usage needs for our client

With 5 people in the family, they required a system that could deliver 10 gallons per minute (gpm). This would allow them to take simultaneous showers while running appliances. All without the fear of “rusty water” entering the home.

The True Definition of “Well Water Problems”

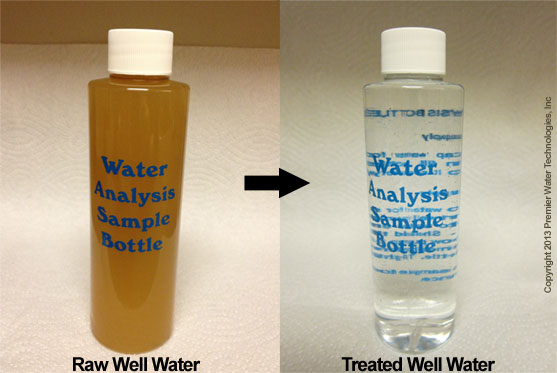

We weren’t surprised when the lab results came back:

High Iron, Iron Bacteria, Manganese, and an acidic pH level.

It was like having an Iron Mine pour out of the faucet!

Raw Well Water Analysis

421ppm Total Dissolved Solids

-0.53 Saturation Index

6.90 pH (neutral pH is 7.0)

200ppm Alkalinity

12gpg Water Hardness

0.1ppm Tannins

1.024ppm Manganese (20x over staining limit)

65.73ppm Iron (219x over staining limit)

Positive Iron Bacteria (creates stinky, corrosive slime)

[divider]

Well Water Treatment Systems that FAILED

The previous system started with an Air Injection Iron Filter. Unfortunately, adding air is similar to putting Iron Bacteria on steroids. It made the problems worse.

The previous system started with an Air Injection Iron Filter. Unfortunately, adding air is similar to putting Iron Bacteria on steroids. It made the problems worse.

Then Hydrogen Peroxide was added as a disinfectant. This had two problems:

- Such extreme levels of Iron require a HUGE oxidation dose for complete precipitation. Such a strong dose of peroxide would break Iron molecules down into micro-particles that pass through the Filter.

- The 9” x 48” tank only has 11.8 gallons of retention volume. It only supported 1.47 gallons per minute (gpm) of use with 8 minutes retention time.

The 10” x 54” Iron Filter was also too small. A 10” Filter only has 0.55 square feet of surface area. It could only handle a “peak” of 3.8gpm.

Lastly, the RUSCO spin down sediment filter was another problem. It plugged up, and required too much maintenance.

A New Water Treatment Systems that WORKS

The new Water Treatment system works in 4 stages:

The new Water Treatment system works in 4 stages:

- Backwashing Filters

- High Backwash Well Water Softener

- Retention, Disinfection, and pH Adjustment

- Polishing Filter

Twin 12” Backwashing Filters

Both filters run in parallel for a total of 1.57 square feet of surface area. This was a 300% increase. Enough to handle 10gpm. Oversized 1.25” Filter Valves were used to minimize pressure drop. Since the water was discolored when drawn from a faucet, we knew that there were significant levels of “Ferric Iron”. Iron that was already oxidized. These Multimedia Depth Filters mechanically strain out the naturally oxidized Iron and Manganese.

High Backwash Well Water Softener

We used a special Well Water Softener with a 1.25” valve. It has an oversized tank with almost 65% more internal volume than conventional Water Softeners. The “Well Water Softener” design uses a flushing mechanism that is 3x more vigorous than a normal Water Softener. A special Resin Cleaning system was also added to help remove Water Hardness and any remaining dissolved “Ferrous Iron” and Manganese.

Retention System with Disinfection and pH Correction

Next, an 80 gallon retention tank was installed after the Water Softener. This tank has 6.7x more mixing time. It supports 10gpm. A chlorine injection system adds small amounts of Chlorine to kill Iron Bacteria. A pH correction system uses a chemical feed pump to raise the pH to minimize corrosion. These systems are both run by the software in the Water Softener controller. Either system can easily be adjusted with a “push of a button”.

Polishing Sediment Filter

The water is now soft, disinfected, non-corrosive, and virtually Iron-Free. Small amounts of Iron can potentially be released when Iron Bacteria is disinfected. A Cartridge Tank Filter was added as a final polishing Sediment Filter to capture any remaining particulate matter. These filters are HUGE. As big as some Water Softeners. They have massive surface area for minimal pressure drop and long service life.

Well Water Problems Solved

The cold water cleared up almost immediately. The toilet tanks had Iron and Bacteria build up that needed to be cleaned. The water heater was also “dirty”. It took several weeks and a few “flushes”, but eventually the hot water cleared up too.

The cold water cleared up almost immediately. The toilet tanks had Iron and Bacteria build up that needed to be cleaned. The water heater was also “dirty”. It took several weeks and a few “flushes”, but eventually the hot water cleared up too.

Well Water Analysis AFTER Treatment

373ppm Total Dissolved Solids

7.87 pH (non-corrosive)

240ppm Alkalinity

0gpg Water Hardness

0.1ppm Tannins

0.000ppm Manganese (Non-Detectable)

0.05ppm Iron (6x below staining limit)

Iron Bacteria – Non-Detectable

About Premier Water

Well water treatment involves careful planning. Premier Water excels at creative, engineered water treatment solutions. Do you have nasty well water? Why not sign up for a Free Site Inspection or give us a call at 952-767-0230 to get started?

Did you try to clean up the well, first, before putting all of that equipment in place?

Yes, and good suggestion! We have found that wells with 5ppm+ Iron should have the casing periodically flushed out by a well driller (not a service we do, but one we often refer).

Do you typically install iron filters before or after the water softener for a house with well water?

What about a sediment filter?

Iron Filters are usually installed first, unless their are tannins or other problems that would prevent oxidation from working correctly. Thanks for posting!