How Iron Filters Work – Part Three

This is the final article in a 3 part series that was written to explain how Iron Filters work. Part One was a broad overview of the Iron Filtration process. Part Two expanded on the three stages of filtration. In this final article we’ll put everything together and design two different sample Iron Filter Systems.

- 8gpm Peak Residential Iron Filter that will provide iron-only filtration for average domestic water use.

- 20gpm Continuous Residential Iron Filter that will provide iron and hydrogen sulfide filtration for both domestic and irrigation use.

By outlining these different systems, you will see that the same principles of water chemistry and physics apply – regardless of system size!

Residential Iron Filter Example

Let’s imagine we have a family of four with average water use of 75 gallons per day/person. Water use is fairly low most of the day, but there are several peaks where multiple fixtures and appliances run at the same time.

We’re going to design a system to treat fairly poor water quality that is typical of well water in Deephaven, Shorewood, Orono, etc:

Water Quality

4.0 Iron (ppm)

0.0 Hydrogen Sulfide (ppm)

7.4 pH

Water Use

2gpm Dishwasher

4gpm Washing Machine

2gpm Toilet

2gpm Faucet

8gpm Total Peak Flow Required

Oxidation Requirements

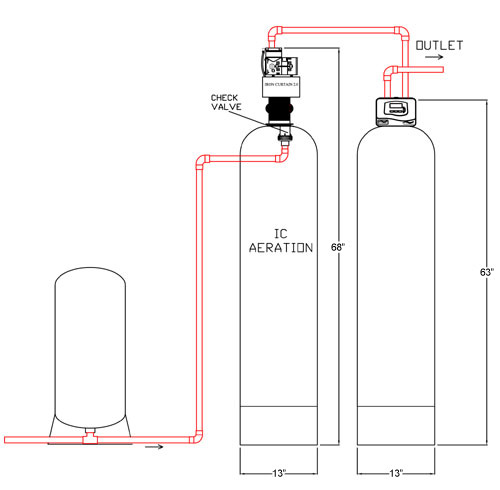

In Part Two, we discussed the amount of time it takes to oxidize Iron. The water quality in this example will require 2 minutes of contact time for full oxidation.

8gpm x 2 minutes = 16 gallons of retention required

A 13” x 54” retention tank holds 18 gallons of water and would be the perfect size for this application.

Filtration Requirements

For this family, we are mainly concerned with their peak water usage of 8gpm. For iron-only removal, we will use a peak specification of 9gpm/sq. ft. due to the high iron level in this well water.

8gpm / 9gpm/sq. ft. = 0.88 sq. ft. of required surface area

A 13” diameter tank has 0.92sq. ft. of surface area, and would deliver 8.28gpm of iron-free water for up to 10 minutes.

Backwash Requirements

The Iron Curtain product line that we carry only requires a backwash rate of 11gpm/sq. ft. The backwash requirement for our 13” diameter filter tank is as follows:

0.92 sq. ft. x 11gpm/sq. ft = 10gpm backwash flow rate

10gpm is a reasonable flow rate to send to most functioning floor drains. A stand pipe would also be a good substitute if the floor drain is inadequate.

The size of drain line is crucial for iron filters. For our 13” filters, we use a 1” drain line to ensure that there is no restriction for the backwash.

Here’s what the complete system looks like:

Sample Irrigation Filter System for Iron and Hydrogen Sulfide

Irrigation with rusty water will not only discolor your home’s exterior, but also destroy your landscaping and hard surfaces like driveways and walk ways.

Irrigation usually takes place before residential water use picks up. So we’re going to design a system that will handle irrigation as well as moderate water use inside a home:

Water Quality

3.0 Iron (ppm)

0.3 Hydrogen Sulfide (ppm)

7.4 pH

Water Use

12.5gpm Irrigation (5 heads @ 2.5gpm/head)

2gpm Toilet

2gpm Faucet

16.5gpm Total Peak Flow Required

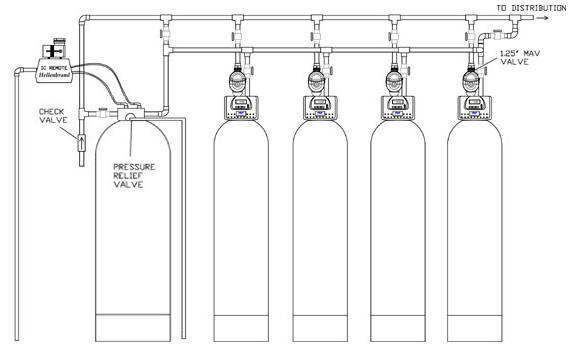

Oxidation Requirements

Because this water contains both Iron and Hydrogen Sulfide, it will require 3 minutes of contact time for full oxidation.

16.5gpm x 3 minutes = 49.5 gallons of retention required

A 21” x 62” retention tank holds 54 gallons of water and would be the perfect size for this application.

Filtration Requirements

This example is not concerned with “Peak Flow” like the first system. Irrigation can run for hours, so we are going to base this system on “Service Flow” for continuous operation.

For Iron and Hydrogen Sulfide removal, we will use a service flow specification of 3gpm/sq. ft. due to the high iron level in this well water.

16.5gpm /3gpm/sq. ft. = 5.5 sq. ft. of required surface area

A 30” diameter tank has 4.9sq. ft. of surface area, and can produce 15gpm of filtered water. Now this is close, but this massive filter would require 54gpm to backwash! That’s too much water for a floor drain or stand pipe. While a daylight drain could work, the pump requirement would be intense! This is not a good idea for almost any application!

Instead, we will use (4) 16” filters that have a total of 5.6sq. ft., and deliver 16.8gpm of clean water.

Backwash Requirements

The backwash rate for each 16” diameter vessel is as follows:

1.4 sq. ft. x 11gpm/sq. ft = 15gpm backwash flow rate

A 15gpm backwash should be drained into a stand pipe, or preferably, a daylight drain.

For our 16” filters, we still use a 1” drain line. Once we get to an 18” filter, we increase the drain line to 1.50” or larger.

Here’s what the complete system looks like:

Summary

Over the years we have built a wide range of Iron Filters for our clients. By using sound science and engineering, you will have predictable results. When you cut corners and build a system based on guesses and dreams, the results are spotty at best!

We hope you have enjoyed this article series. Please feel free to share it with friends, colleagues, or anyone that has water problems. If you have rusty, stinky well water, we would love the opportunity to help you conquer it – for good!

Who We Are

Premier Water is a local, family-owned water treatment company based in Chanhassen, MN. Since 1978, Premier Water has successfully implemented 1000’s of Residential and Commercial Iron Filters to treat a variety of well water conditions. We offer a FREE WATER TEST to gather information and help our clients with the right solution for their needs. We can also be reached at (952) 479-4553 for more information.

Very true! Makes a change to see someone spell it out like that. 🙂

Why is my iron filter #3 reservoir releasing purple water on the floor from the over flow spout? What should I do?

This must be a Greensand Iron Filter that regenerates with Potassium Permanganate. There is a problem with the brine valve assembly.

Thanks for posting!

Lars